Description

Covering type – rutile-cellulose

| AWS A 5.1:E 6013 | ISO 2560-А-E 42 0 RC 11 |

APPLICATION CONDITIONS

Deposition rate factor – 8,5-9,5 g/А.hr. Electrode consumption per 1 kg of deposited metal is 1,7 kg.

Electrodes “ ROT-ERZ” suitable for corner, butt and fillet joint types on metal with 3-20 mm thickness. Electrodes with diameter range from 2 to 4 mm applicable in all welding positions. Electrodes with diameter 5 mm can be used in horizontal flat, horizontal down hand, transverse and vertical up positions.

Welding in vertical down position is carried out by short arc or deep-penetration method, herewith electrode must be in bisector flat area and the travel angle may vary 40 – 70°.

CHEMICAL COMPOSITION OF DEPOSITED METAL, %

|

Mn |

C |

Si |

P |

S |

|

0,40-0,75 |

||||

|

0,11 |

0,15-0,35 |

0,035 |

0,035 |

MECHANICAL PROPERTIES OF WELD METAL

|

Tensile strength, N/mm2 |

Elongation, % |

Impact strength, J/cm2 |

|

≥450 |

≥22 |

≥78 |

Particular characteristics

Electrodes “ ROT-ERZ” have improved formula that provides improved welding and technological properties, working from small (domestic) transformers, namely: easy initial arc ignition, forming small-scope metal joint, easy self-peeling slag. It is possible using for tacks, short and root welding beads at low voltage in a system.

PACKING DATA

|

Diameter, mm |

Length, mm |

Current, А |

Electrode weight, g |

Quantity of electrodes in a package, pc |

Package weight, kg |

|

2,50 |

350 |

50-100 |

17-18 |

135-143 |

2,5 |

|

3,20 |

350 |

80-130 |

30-31 |

82-85 |

2,5 |

|

4,00 |

450 |

110-180 |

58-59 |

84-87 |

5 |

|

5,00 |

450 |

150-230 |

91-92 |

54-55 |

5 |

BACKING BEFORE WELDING

At the normal storage conditions, the electrode baking is not required. In case of moisture the baking is made at 110±10°С for 40-60 min.

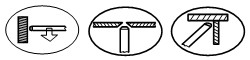

WELDING POSITIONS

PA PB PC PF

PG PE PD EN 287